So far this week here at The Button Blog we have discussed myths about Chinese 3-in-1 button makers, provided a price comparison between American-made all-in-one button making kits and Chinese all-in-one button making machines, and contrasted the great usability and design of American-made button makers with their Chinese-made counterparts.

Today, in the final installment of our four-part, weeklong lesson on the differences between American-made button machines and Chinese-made button machines, we are going to discuss the significant differences in manufacturing quality.

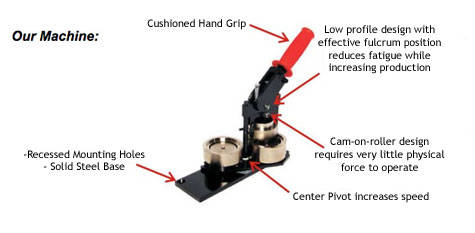

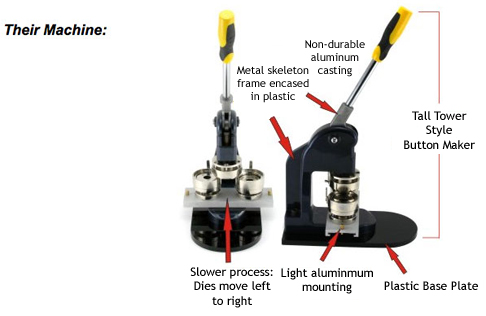

If you read yesterday’s post, you will recognize the next two images. We are posting them again for use as reference while you read the rest of this post.

If you look at the picture above, it looks like the Chinese machine is made entirely of steel. However this is not true.

The Chinese machine has an internal metal “frame” that has a plastic covering applied over it and is then painted. This begs the question, in our mind, why would you cover metal with a thick plastic?

There are a few potential reasons that we can surmise:

- To cover rust during the import process.

- To make it look like the entire machine is larger and made entirely of metal.

- To cut corners and save money, which has long been a criticism of Chinese-made products in general. (Of course, as we noted in our previous button maker kit comparison article, despite the lower quality of the Chinese-made button machines, they are still more expensive.)

If you look at the Chinese-made machine it has a long handle and is very tall. The bottom plate that the machine is attached to is made of some sort of plastic that, because it is not made of metal, can easily break.

The base plate is used to stabilize the top-heavy machine. However, when the handle is pulled down during the button making process, the back of the machine can rise up off the table quite easily, which could result in the machine tipping over.

Think about the ergonomics of such a design: if you have a large button order and are sitting down to make the buttons, you have to raise your arm fairly high to reach the handle every time you press a button.

To the contrary, our machine is not top heavy like the competition’s tower machine, so you do not have to secure our machine to a base plate. However, we do provide screw holes in the base of our machine if you wish to mount it to a portable board or secure it to a table. If you are looking for a mounted button making system with a professional look, we also offer snazzy-looking professional mounted button maker systems.

When making a button, most of the force to press it together is transferred where the handle meets the machine. What has China designed for this integral exchange of power? Another cheap part that is not durable:

As you can see in the picture, the handle is threaded through what looks to be an aluminum metal casting, not solid metal. Casting is an inexpensive process by which liquid material is poured into a mold. It is not anywhere as strong as solid steel, and castings can break if too much force is exerted on them.

Again, this raises serious questions in our minds:

- Why would you make such an important part of a button machine out of a cheap manufacturing process?

- What if this casted part breaks?

- Your button machine is imported, where do you get replacement parts?

Another area where you will find that Chinese button machine manufacturers have cut corners is in the threads in the casting where the handle is attached (see arrows in picture). The casting aluminum is so soft that if you screw the handle in the wrong way you can ruin the threads.

I am sure that, like most people, you have screwed something in the wrong way when trying to put a product together. For instance, when you buy a build-it-yourself desk sometimes the desk comes with specially-sized yet cheap screws that you are forced to use and that are easy to strip if you are not extremely careful. If you strip the screws, you are, well, out of luck. You then have to purchase more or be content trying to rig the desk together in a way that will most likely not be sturdy and result in a finished product that is not what you paid for.

As they say, a chain is only as strong as its weakest link. Well, a button machine is only as strong as the handle attachment. Chinese-made button machines make the strength of the handle attachment quite precarious, so why risk it?

In conclusion, our extensive research on this topic has found that American-made button maker kits are better than their Chinese counterparts in the following ways:

- Less costly.

- Greater manufacturing quality.

- Easier to use.

- More time-efficient.

Plus, echoing our conclusion to the first post on this subject, a USA-made button maker supports the “home team.” And when the home team’s product is better in virtually every possible way, why wouldn’t you want to buy American?

Make the smart choice today and choose from the absolute best button machine products on the market:

Button Maker Kits from American Button Machines

Brighid Brown – Director of Blogging and All Things Cool at ABM